Safety, reliability, and long-term viability: it is

all just a question of the right control system.

We are experts in automated processes

that drive technical progress.

Automation

The team at EMIS are experienced experts in all aspects of automation. Whether your request concerns industrial manufacturing and machining processes, safety-related or potentially explosive areas, transporting people or retrofitting existing facilities, we are always glad to lend our expertise to your project.

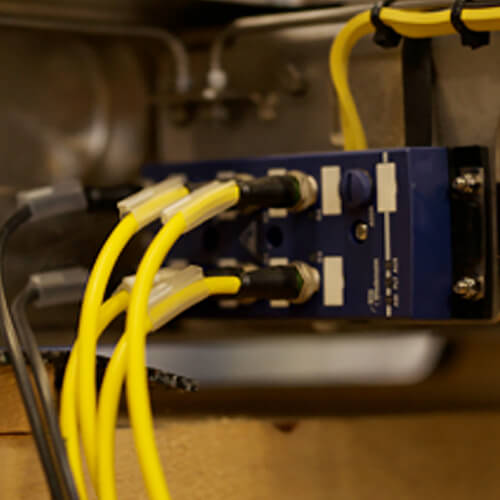

From analysis and engineering to realisation, commissioning and maintenance, our portfolio covers every aspect of the product lifecycle. Our services go beyond the conventional focus on bespoke and mass production. Our IoT segment supports smart big data solutions, digital twins, and predictive maintenance. These are what make our plant and ride control systems so cutting-edge, highly effective, and highly available.

Your personal contact

Harald Gehring

info@emis-gruppe.de

EMIS can guide you through the entire process. We start by analysing your current situation and defining your specific requirements. Our services range from selecting appropriate component manufacturers to generating your personal, intuitive operating concept and risk assessment. EMIS grants you a clear and comprehensive understanding of what the planned facility can do.

- Analysing existing facilities

- Helping you to define requirements

- Customer-focused approach to finding solutions

- Customised control systems

- Compliant with DIN EN/ISO 13849 or IEC 61508 safety standards

- Selecting the best component manufacturers

Engineers to the core, we get excited when things get complicated. Our customers’ individual requirements are always at the forefront of our minds.

User-friendliness, efficiency, and long-lasting, sustainable solutions are what we at EMIS are all about. This reduces the necessity for job-specific training, keeps set-up times to a minimum, and ensures maximum efficiency through full utilisation of all facilities.

- Customer-focused and bespoke engineering

- Manufacturer-independent development and programming

- Graphically appealing intuitive touch-screen solutions

- High usability

- Hardware diagrams using EPLAN Electric P8

- SPS programming

- Selecting the best component manufacturer(s) based on customer requirements

- Safety-focused control systems based on DIN EN/ISO 13849 or IEC 61508 standards

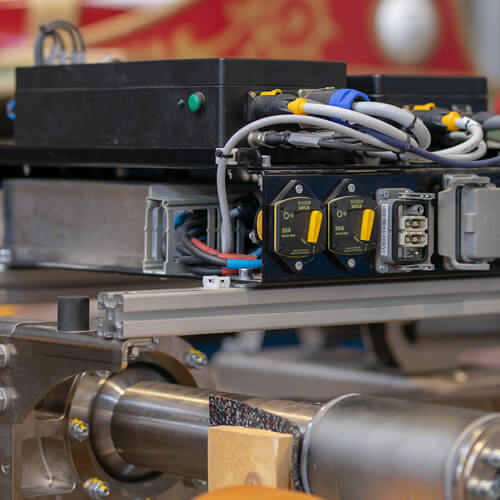

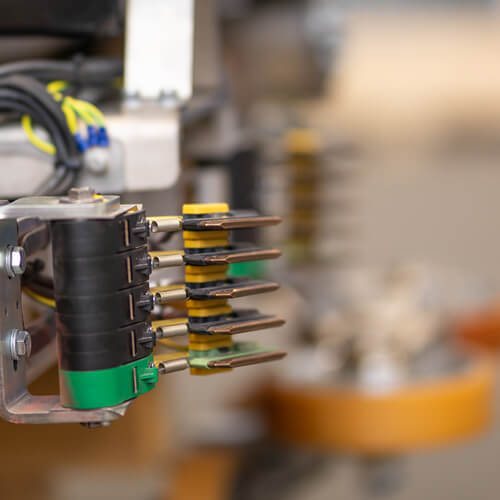

We manufacture plant and ride control systems at multiple locations across Germany, precisely to meet your needs. The highest quality standards, state-of-the-art production facilities, and a digitalised final inspection procedure ensure smooth and future-proof solutions. We ship worldwide and take care of installing the plant and ride control systems. Our many years of experience guarantee smooth and speedy approval by national testing authorities.

- CNC-supported mass production and one-off items

- Production certified to UL 508A standard

- Approval by national testing authorities

- Manufactured in Germany

- Installing systems worldwide

- Providing a supervisor

- In-house assembly personnel

- Commissioning of systems worldwide

- Approval by local and international certification authorities

- Endurance testing

- In-house commissioning personnel

We see ourselves as both diligent caretakers and proactive doers – ensuring our customers have as little to worry about as possible. We make sure that deadlines are met and that projects go to plan. We also do everything from preparing the specifications to obtaining approval from local authorities on site. Costs, deadlines, quality – you can trust EMIS to deliver on all expectations.

- Experience managing projects worldwide

- Extensive experience working with staff and testing authorities in destination countries

- Highly flexible and customer-focused approach

- Project management in safety-critical areas

Complete, transparent, and current documentation is an all-round must: from commissioning to maintenance and upgrading of facilities. EMIS always provides the latest version of all documents in digital form, supported by a database.

- Compliance with DIN EN 82079-1/IEC 82079-1 standards

- Provided in HTML5, PDF, and Word formats, as well as a mobile app

- Intuitive and clearly structured instructions

- Preparation of facility-specific training documents

- Provided in HTML5, PDF, and Word formats, as well as a mobile app

- Digital final audit with automatic evaluation and archiving

- Generation of an audit certificate

- Safety documentation including determining the performance level in accordance with DIN EN ISO 13849-1

- Safety documentation including determining the SIL levels as per IEC 61508, Levels 1-4

- All tests can be completed in digital format

- Factory Acceptance Testing (FAT)

- Site Acceptance Testing (SAT)

- Safety testing

- I/O testing

- Hardware diagrams and circuit diagrams using EPLAN Electric P8

- Theoretical training both in-house and on-site

- Practical training for operational and maintenance personnel on-site

- Training at the EMIS training centre

Application areas

Clients

EU sponsorship project from EMIS LEARN MORE HERE